As an indispensable tool in machining, the life of cutting tools directly impacts machining efficiency and production costs. Short tool life not only leads to frequent tool changes and increased production costs but also affects machining accuracy and product quality. So, how can we effectively extend tool life? Today, we’ll share some practical solutions.

Selecting the Optimal Tool Material

Tool material is one of the most critical factors affecting tool life. Different workpiece materials and machining processes require different tool materials. For example, high-speed steel (HSS) tools offer good toughness and are suitable for machining ductile materials; carbide tools provide high hardness and wear resistance, ideal for high-speed cutting; ceramic tools deliver even higher hardness and wear resistance, making them suitable for high-strength, hard materials. When selecting tool materials, it is important to consider factors such as workpiece properties, process requirements, and machine capabilities to choose the most suitable tool material and maximize tool life.

Optimize Cutting Tool Geometry

Tool geometry greatly influences tool life. Proper geometry enhances cutting performance, reduces cutting forces and heat generation, and extends tool life. For instance, increasing the rake angle lowers cutting forces and heat, though excessive rake can weaken tool strength; increasing the clearance angle reduces friction between tool and workpiece, but too much clearance can also reduce strength. Parameters such as edge radius, main cutting edge angle, and minor cutting edge angle should be fine-tuned according to machining requirements. By optimizing geometry, tools can maintain stable cutting conditions, minimize wear, and achieve longer service life.

Control Cutting Parameters

Cutting parameters include cutting speed, feed rate, and depth of cut. Properly controlling these parameters can effectively reduce tool wear and extend tool life. In general, higher cutting speeds result in faster tool wear, while excessively low speeds lead to low machining efficiency. Therefore, it is necessary to select an appropriate cutting speed based on both the workpiece material and the tool material. Feed rate and depth of cut also influence the degree of tool wear—excessive values can cause a sharp increase in cutting forces and heat, accelerating wear. Thus, while ensuring machining quality, smaller feed rates and depths of cut should be used whenever possible to prolong tool life.

Apply Effective Cooling and Lubrication

Effective cooling and lubrication reduce cutting temperatures, minimize tool wear, and extend tool life. Common methods include water-soluble cutting fluids (excellent cooling, ideal for high-speed cutting), oil-based cutting fluids (superior lubrication, suitable for low-speed cutting), and compressed air cooling (used when liquid coolants are restricted). Select the method based on workpiece material, tool properties, and process requirements to achieve optimal results.

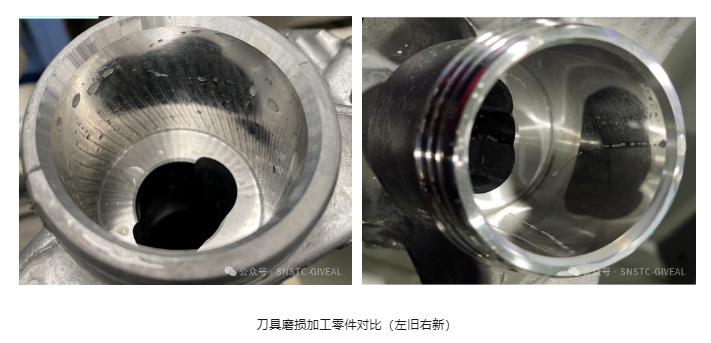

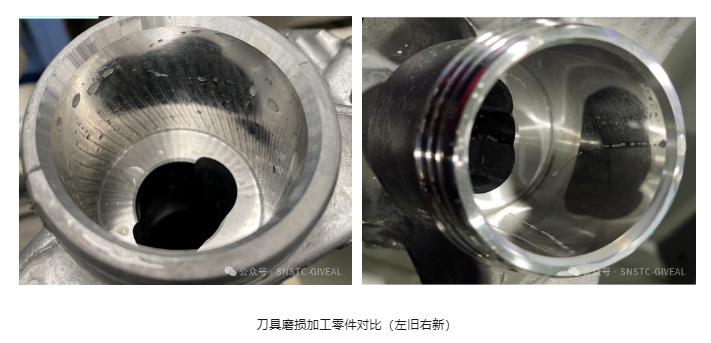

Timely Inspection and Maintenance of Tool Wear

Tool wear is inevitable, but timely detection and maintenance can significantly extend tool life. During machining, regularly inspect for common wear patterns such as flank wear, crater wear, and nose wear. When wear reaches the specified limit, promptly regrind or replace the tool. Keep tools clean to prevent chips or contaminants from affecting cutting performance. Proactive maintenance ensures optimal cutting conditions and maximizes tool life.

Improve Operator Training

Improve Operator Training

The skill level of operators plays a crucial role in tool life. Operators should be well-versed in proper tool usage and safety precautions, strictly adhering to process specifications. This includes correct tool installation, precise adjustment of cutting parameters, and prompt replacement of worn tools. They should also master tool wear inspection methods and maintenance skills to detect and address issues during machining. Enhanced operator training helps minimize tool damage from improper handling and extend tool life.

Conclusion

Tool life is a critical factor in machining, but with the right approach, it can be significantly extended. By selecting suitable tool materials, optimizing geometry, controlling cutting parameters, applying effective cooling and lubrication, performing timely inspection and maintenance, and enhancing operator training, you can boost productivity, reduce costs, and maximize tool performance. We hope these methods help you tackle tool life challenges—let’s work together to improve and innovate! If you have questions or suggestions, feel free to reach out for discussion.

Selecting the Optimal Tool Material

Tool material is one of the most critical factors affecting tool life. Different workpiece materials and machining processes require different tool materials. For example, high-speed steel (HSS) tools offer good toughness and are suitable for machining ductile materials; carbide tools provide high hardness and wear resistance, ideal for high-speed cutting; ceramic tools deliver even higher hardness and wear resistance, making them suitable for high-strength, hard materials. When selecting tool materials, it is important to consider factors such as workpiece properties, process requirements, and machine capabilities to choose the most suitable tool material and maximize tool life.

Optimize Cutting Tool Geometry

Tool geometry greatly influences tool life. Proper geometry enhances cutting performance, reduces cutting forces and heat generation, and extends tool life. For instance, increasing the rake angle lowers cutting forces and heat, though excessive rake can weaken tool strength; increasing the clearance angle reduces friction between tool and workpiece, but too much clearance can also reduce strength. Parameters such as edge radius, main cutting edge angle, and minor cutting edge angle should be fine-tuned according to machining requirements. By optimizing geometry, tools can maintain stable cutting conditions, minimize wear, and achieve longer service life.

Control Cutting Parameters

Cutting parameters include cutting speed, feed rate, and depth of cut. Properly controlling these parameters can effectively reduce tool wear and extend tool life. In general, higher cutting speeds result in faster tool wear, while excessively low speeds lead to low machining efficiency. Therefore, it is necessary to select an appropriate cutting speed based on both the workpiece material and the tool material. Feed rate and depth of cut also influence the degree of tool wear—excessive values can cause a sharp increase in cutting forces and heat, accelerating wear. Thus, while ensuring machining quality, smaller feed rates and depths of cut should be used whenever possible to prolong tool life.

Apply Effective Cooling and Lubrication

Effective cooling and lubrication reduce cutting temperatures, minimize tool wear, and extend tool life. Common methods include water-soluble cutting fluids (excellent cooling, ideal for high-speed cutting), oil-based cutting fluids (superior lubrication, suitable for low-speed cutting), and compressed air cooling (used when liquid coolants are restricted). Select the method based on workpiece material, tool properties, and process requirements to achieve optimal results.

Timely Inspection and Maintenance of Tool Wear

Tool wear is inevitable, but timely detection and maintenance can significantly extend tool life. During machining, regularly inspect for common wear patterns such as flank wear, crater wear, and nose wear. When wear reaches the specified limit, promptly regrind or replace the tool. Keep tools clean to prevent chips or contaminants from affecting cutting performance. Proactive maintenance ensures optimal cutting conditions and maximizes tool life.

The skill level of operators plays a crucial role in tool life. Operators should be well-versed in proper tool usage and safety precautions, strictly adhering to process specifications. This includes correct tool installation, precise adjustment of cutting parameters, and prompt replacement of worn tools. They should also master tool wear inspection methods and maintenance skills to detect and address issues during machining. Enhanced operator training helps minimize tool damage from improper handling and extend tool life.

Conclusion

Tool life is a critical factor in machining, but with the right approach, it can be significantly extended. By selecting suitable tool materials, optimizing geometry, controlling cutting parameters, applying effective cooling and lubrication, performing timely inspection and maintenance, and enhancing operator training, you can boost productivity, reduce costs, and maximize tool performance. We hope these methods help you tackle tool life challenges—let’s work together to improve and innovate! If you have questions or suggestions, feel free to reach out for discussion.